Thomas Livestock

Case Study: Converting From Stall Housing to Group Gestation Pens

Challenge

In 2012, Thomas Livestock was in the planning phase for building a new 5500 head sow barn. The team planned on simply going with traditional gestation stalls since that is what they had in their current operations. They had never experienced a group sow housing design that reduced stress among sows and had production numbers as high as stall barns. Thomas Livestock's General Manager Tim Friedel had plenty of experience with group gestation pens, but every design he had managed or experienced was more stressful on the sow. Every time he had tried to mix animals, it resulted in a high level of fighting. The team was concerned with animal welfare in their barns and the ability to implement technology in their operations down the road. They were still open to group housing, but they had not yet found a viable solution.

Before settling on a gestation stall barn design, they decided to see how successful current group housing designs were, and they started traveling around the U.S. visiting different barns with different group housing systems. On these trips, they didn't come up with anything they were interested in, so they were just going to stick with their gestation stall plans.

The Solution

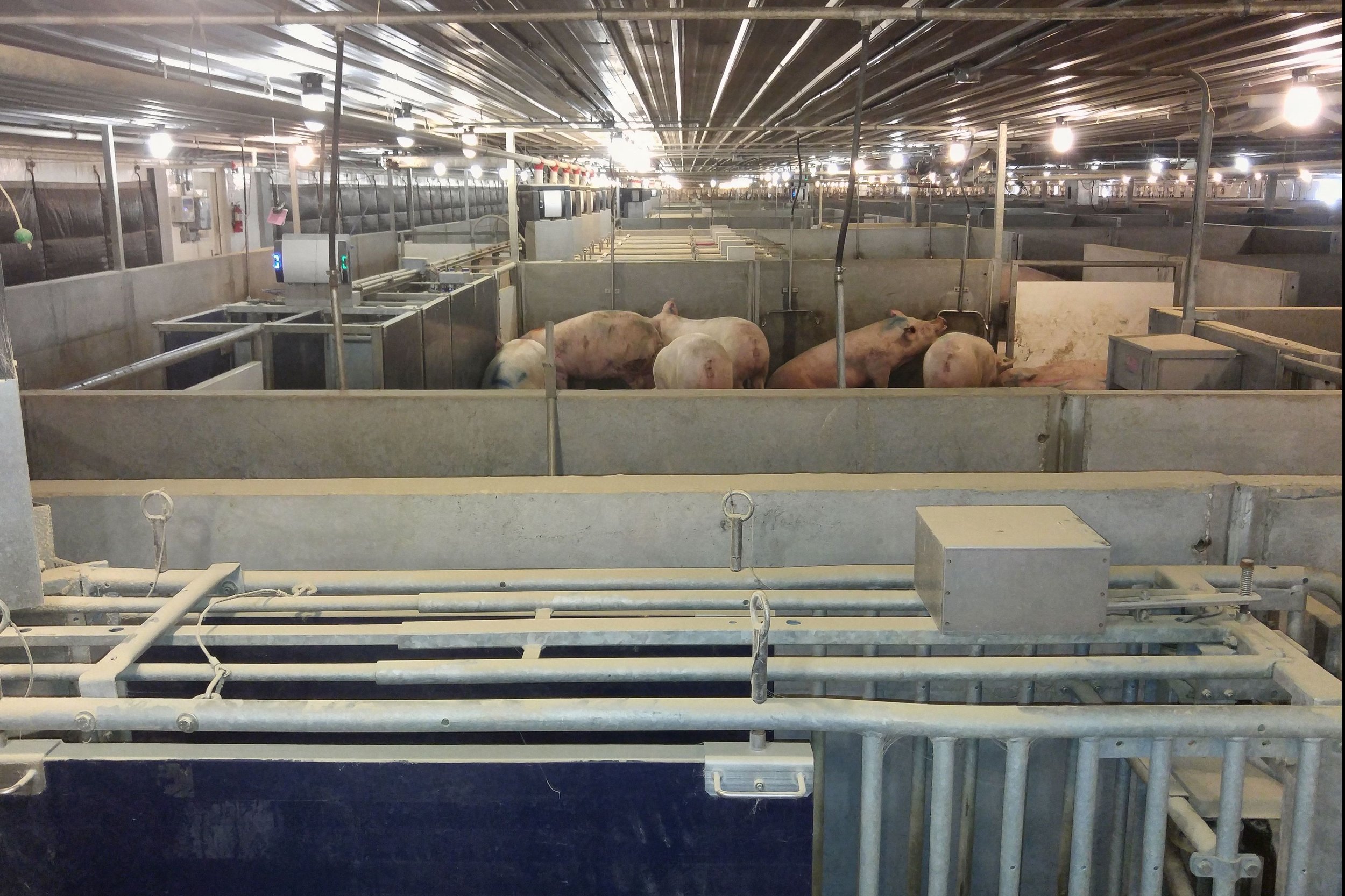

As the team got deeper into planning, they received a call from a friend that suggested they tour a newly built group housing and electronic sow feeding barn that was designed by the New Standard Group. They agreed to tour the barn, and as they went through system, which had been installed that year, they were impressed with the design. It answered a lot of their questions and eased the reservations they had with most loose housing systems.

With a New Standard group gestation pen design, they saw that there was less stress on the animals. There was a noticeable difference in each sow and how she behaved; she was relaxed and calm. This was the first barn that Tim thought there was a real opportunity to actually reduce stress on sows.

"In all other group housing barns, I felt like I saw more stress factors, a little more lameness, a little bit higher sow mortality and lower farrowing rates and conception rates. I didn't see that really good productivity coming out, and to me that is a very key factor. It's hard to have a really productive farm with stress."

- Tim Friedel, General Manager

Tim believed that if the system works for one person, it should work for him if Thomas Livestock could adapt to the best practices of this group housing system. Even though they were not interested in group housing at the time, the system sold itself and they made the decision to go ahead and do a full 360 and change their barn plans to a New Standard Group group sow housing design.

The Results

When it comes to conception, farrowing, weaning, lameness, and mortality, all the numbers in their group sow housing barns are within the margin of error. Productivity in their loose housing and stall barns, including the first year of operation, has been almost identical.

Building the group housing barn cost Thomas Livestock about 5% more than a traditional stall barn. When asked whether increased production can make up for the extra 5%, Tim will tell you they believe from a productivity standpoint, they are still learning daily how to manage the building to the best of their ability, so there is more room for improvement. Where they strongly believe they will return the value is in the future. They plan on operating these barns for 40 years, and they feel that New Standard's design and equipment is the best suited for adapting to future technologies, things they are doing research on today.

"We're starting to really look into cameras and different things that we can do with the Electronic Sow Feeders, and I think there's going to be a big payback in the future. To me, that's where it's worth the 5% investment. I have a barn now that will really adapt."

-Tim Friedel

Thomas Livestock has tours through their barns every week through the summer. On every tour, they hear comments from their guests that they feel like this is truly better for the sow.

"It's just a human nature. If you look at them, you say well yeah I mean they're better off here than they were in a crate. Really, it's the first group housing system that I've seen personally that I believe actually reduces the stress as it relates to a crate....I'm eating my words now as I'm explaining to other producers why this system is better."

-Tim Friedel

Thomas Livestock has now converted all of their sow barns to a New Standard Group design except their oldest barn, which will still be crated for a few more years. In the meantime, they have plans of building a brand new ESF barn to replace this barn.